Goal:

Develop a container for silica gel (desiccant) to keep filament dry during storage.

Requirements:

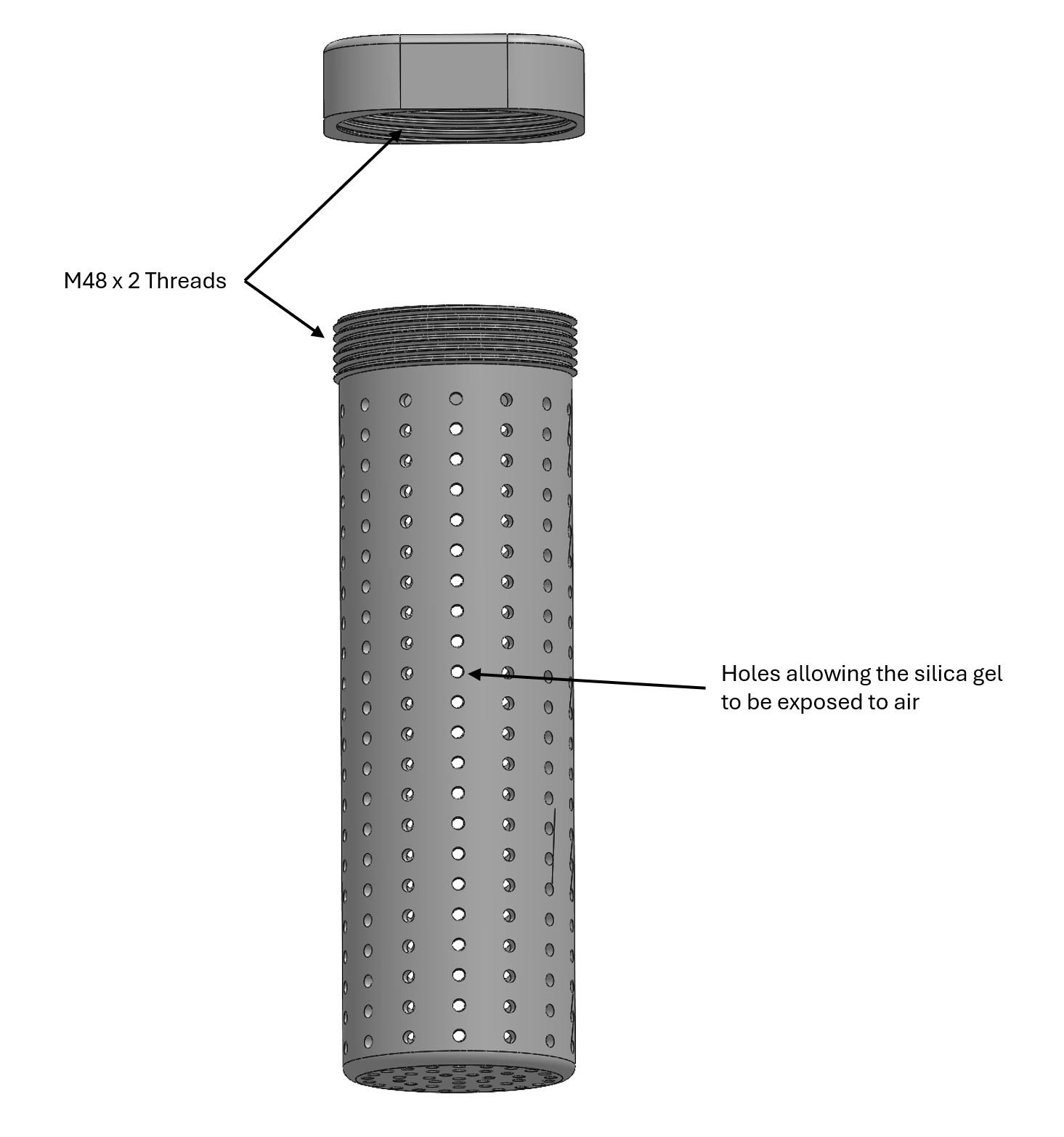

- Perforated design to allow silica gel to absorb humidity effectively.

- Threaded connection to securely combine the cap and cylindrical container.

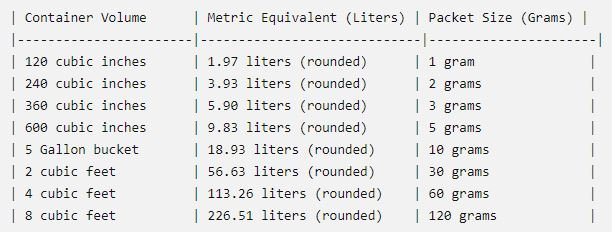

- Sufficient capacity to maintain low humidity for a 4590 in³ (2.66 ft³) filament container.

Design Highlights:

- Thread Selection: Used Machinery's Handbook to determine M48 x 2 thread size for this large application, as SolidWorks lacked default options. Multiple iterations ensured proper 3D printability and functionality.

- Perforation Design: A large number of holes maximize airflow exposure to the silica gel.

- Silica Gel Capacity: Designed for ~172 g (0.189 quarts) of silica gel—over 3 times the estimated requirement (45 g) to minimize refill frequency.

Outcome:

The final design successfully meets all requirements, providing:

- Effective Humidity Control: High perforation density for maximum air exposure.

- Secure Fit: M48 x 2 threading for reliable assembly.

- Ample Capacity: 172 g of silica gel, ensuring prolonged moisture control for a 4590 in³ (2.66 ft³) filament container.